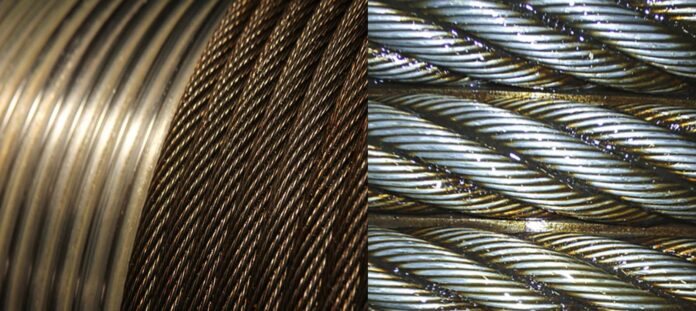

Wire lubrication is a complex task, regardless of structure and composition. As per wire lubrication expert ViperWrl the ropes that have fiber cores are a little more lubricated than those constructed entirely from steel material. This is why it is essential to think about the subject of field lubrication prior to selecting a rope for a particular application.

Wire rope lubricants serve two main purposes:

- To minimize friction when the wires cross each other.

- to provide corrosion protection and lubrication of the wires’ core, inside and on exterior surfaces.

There are two kinds of lubricants for wire rope coated and penetrating.

Penetrating lubricants are made up of an oil solvent that transfers the lubricant to the wire rope’s core. The solvent evaporates and leaves behind a strong lubricating layer that protects and lubricates each strand. Lubricants coated with coatings penetrate slightly and seal the exterior and inside of the cable to keep out moisture, and reduce the wear of cables as well as fretting corrosion due to contact with other bodies.

Two kinds of lubricants used for wire rope are employed. However, since most wire ropes fail on the inside out, it’s essential to ensure that the center core gets adequate lubrication. A method that combines the lubricant penetrates to fill the core with lubricant, then a coating is applied to protect and seal the exterior surface. Wire rope lubricants include gasoline tatum, asphaltic or petroleum oils, grease or vegetable oils.

Petrolatum compounds, when combined with appropriate additives, offer outstanding resistance to water and corrosion. Additionally, the compounds of petroleum are transparent, which allows technicians to conduct visual inspection. Petroleumatum lubricants may drip away at high temperatures, but retain their consistency even when temperatures are cold.

Asphaltic compounds usually dry to a dark and hardened surface, which makes it difficult to inspect. They are able to hold up well in storage, however they can break and become brittle in colder conditions. They are the type of coating.

Many kinds of greases are utilized to provide lubrication for wire rope. They are the types of coating that penetrate only partially, but don’t infiltrate the rope’s core. The most commonly used grease thickeners are lithium, sodium, complex as well as aluminum-based complex soaps. Greases used for this purpose typically have a semifluid, soft consistency. They coat and allow partial penetration when used with pressure greases.

Oils from vegetable and petroleum penetrate well and are easy to use because the correct addition design for these types provides the best corrosion and wear resistance. The fluid properties of oil-based lubricants aids to clean the rope and remove the abrasive contaminants from outside.

The lubrication of wire ropes occurs in the process of manufacturing. If the rope is made with an inner core of fiber that is coated with natural oil, or petrolatum fluid. The fiber core will absorb oil and act as a reservoir that can provide long-term maintenance of lubrication.

If the rope is made of an iron core and a fluid (both grease and oil) is pumped through the stream that is just before the die, which is used to twist the wires into a braid. This ensures complete coverage of the wires.

Once the cable has been used after installation, it’s necessary to replenish the lubricant due to the loss of initial lubricant due to loading with, stretching, and bending of the cable. Core cables made of fiber get dry as time passes due to the heat from evaporated water, and can also absorb moisture. Field lubrication is essential to prevent corrosion, safeguard and maintain the rope wires and core which in turn extends the life span of the rope.

If a cable is filthy or has layers of hardened lubricant, or any other contaminants It must be scrubbed using a wire brush compressed air, petroleum solvent or steam cleaner prior to the relubrication. The wire rope needs to be dried and lubricated as soon as possible to stop rust from occurring. Field lubricants are applied using spray or dip, brush or drip, or even a pressure boot.

Lubricants are most effective when applied on the sheave or drum in situations where rope strands have a tendency to break due to bending . This allows for maximum contact with the core. If the pressure boot application is employed then the lubricant will be applied using some tension, in a straight state. The application of excessive lubricant should be avoided to minimize the risk of injury to persons.